Homepage "

Homepage "

MASCHINENPARK

MASCHINENPARK

OUR

MACHINE PARK

OUR MACHINERY

OUR

MACHINE PARK

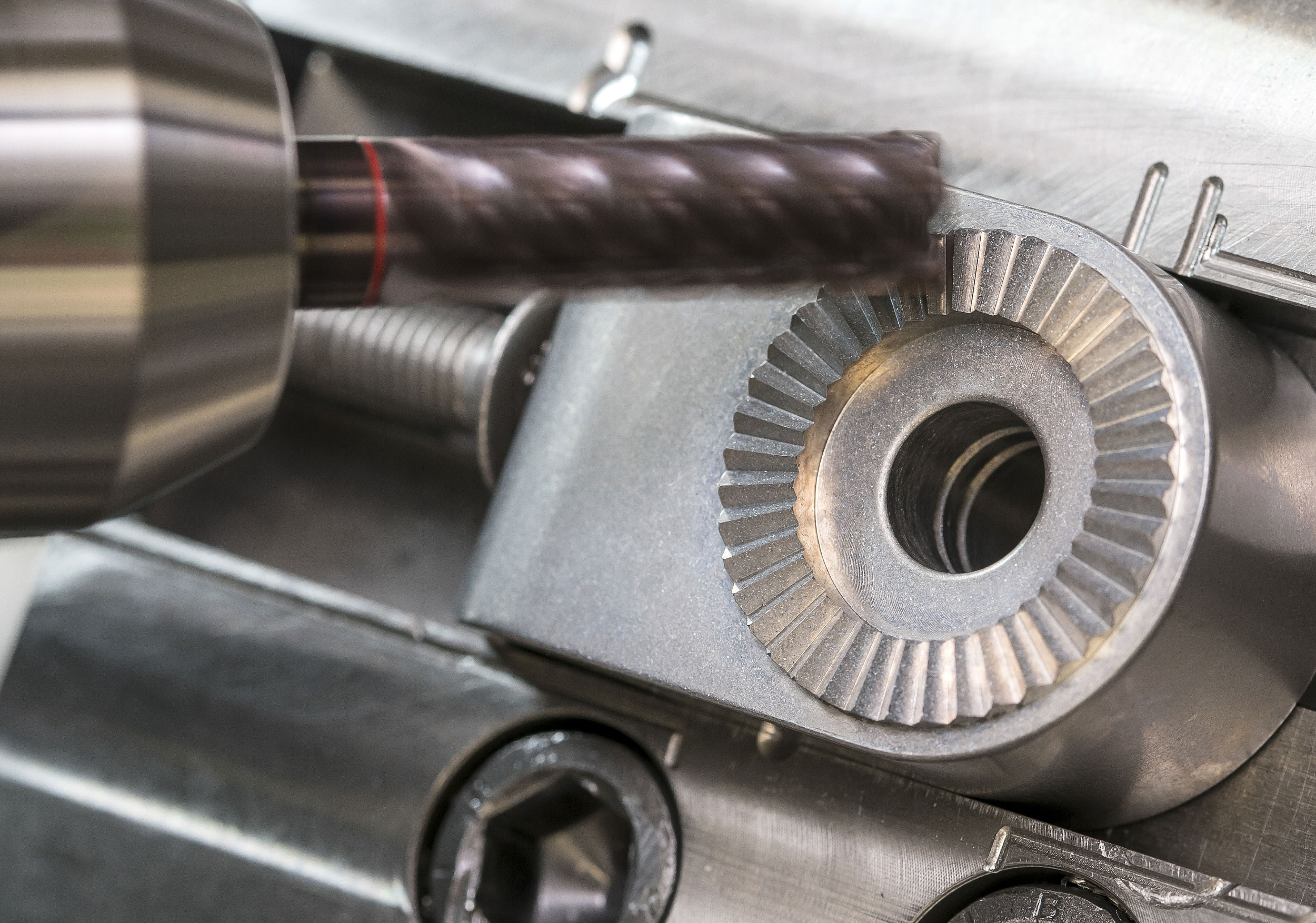

The machinery is the heart of our modern, precise production. The equipment - all from leading manufacturers - is state of the art and ensures that CONDOR® Custom Solutions high-quality results tailored to the customer are always achieved.

The value of our machines, in combination with the professional competence of our employees, is the guarantee that we continuously maintain our accustomed excellent quality level, even in the case of demanding problems.

The machinery is the heart of our modern, precise production. The equipment - all from leading manufacturers - is state of the art and ensures that CONDOR® Custom Solutions high-quality results tailored to the customer are always achieved.

The value of our machines, in combination with the professional competence of our employees, is the guarantee that we continuously maintain our accustomed excellent quality level, even in the case of demanding problems.

Continuous development using technological advancements and new materials is the driving force behind our consistent, high-quality workmanship. Innovative wire-cut EDM technology, 5-axis milling technology, and a 3-D measuring machine (ZEISS CONTURA GA) are some of the components in our production that ensure this high quality standard.

Complementing our quality, flexibility sets another outstanding accent in the manufacture of our products. This allows us to react flexibly to special market requirements and the specific needs of our customers: with individually tailored solutions in proven, top quality. CONDOR® Custom Solutions quality.

Maximum quality standards apply not only to our own manufacturing and production: The products of our suppliers are also subject to our high quality standards and are audited and certified. Therefore, users of our devices can be sure to hold only the best and tested quality work in their hands. The platform for this is the certification according to EN ISO 13485:2016.

Continuous development using technological advancements and new materials is the driving force behind our consistent, high-quality workmanship. Innovative wire-cut EDM technology, 5-axis milling technology, and a 3-D measuring machine (ZEISS CONTURA GA) are some of the components in our production that ensure this high quality standard.

Complementing our quality, flexibility sets another outstanding accent in the manufacture of our products. This allows us to react flexibly to special market requirements and the specific needs of our customers: with individually tailored solutions in proven, top quality. CONDOR® Custom Solutions quality.

Maximum quality standards apply not only to our own manufacturing and production: The products of our suppliers are also subject to our high quality standards and are audited and certified. Therefore, users of our devices can be sure to hold only the best and tested quality work in their hands. The platform for this is the certification according to EN ISO 13485:2016.

Continuous development using technological advancements and new materials is the driving force behind our consistent, high-quality workmanship. Innovative wire-cut EDM technology, 5-axis milling technology, and a 3-D measuring machine (ZEISS CONTURA GA) are some of the components in our production that ensure this high quality standard.

Complementing our quality, flexibility sets another outstanding accent in the manufacture of our products. This allows us to react flexibly to special market requirements and the specific needs of our customers: with individually tailored solutions in proven, top quality. CONDOR® Custom Solutions quality.

Maximum quality standards apply not only to our own manufacturing and production: The products of our suppliers are also subject to our high quality standards and are audited and certified. Therefore, users of our devices can be sure to hold only the best and tested quality work in their hands. The platform for this is the certification according to EN ISO 13485:2016.

ADDITIVE MANUFACTURING

ADDITIVE MANUFACTURING

The field of "additive manufacturing processes" and especially 3D printing is based on layer technology. The additive manufacturing process is used to produce series parts or functional prototypes in 3D from plastic, which are characterized above all by a constant component quality.

Installation space:

Max. Installation space 330 x 330 x 600 mm

Details:

Material used: Polyamide PA 12

Year of manufacture: 2018

The field of "additive manufacturing processes" and especially 3D printing is based on layer technology. The additive manufacturing process is used to produce series parts or functional prototypes in 3D from plastic, which are characterized above all by a constant component quality.

Installation space:

Max. Installation space 330 x 330 x 600 mm

Details:

Material used: Polyamide PA 12

Year of manufacture: 2018

WIRE EDM TECHNIQUES

WIRE EDM TECHNIQUES

DRAHTERODIER-

TECHNIQUES

Travel: x/y/z 500 x 350 x 300 mm

Workpieces up to 1500 kg

Workpiece size 1050 x 800 x 295 mm

Year of manufacture: 2007

Travel: x/y/z 400 x 300 x 220 mm

Workpieces up to 500 kg

Workpiece size 810 x 700 x 215 mm

1 x year of construction: 2015 and 4 x year of construction: 2020

Travel: x/y/z 400 x 300 x 400 mm

Hole diameter: 0.3-3 mm

Year of construction: 2021

MILLING TECHNIQUES

MILLING TECHNIQUES

travels:

x/y/z 650x650x560 mm

Details:

Max. Speed: 18.000

Workpieces up to 600 kg

Swivel angle: -120° to +120

Control: Heidenhain 530i

Year of manufacture: 2011

travels:

x/y/z 750x650x560 mm

Details:

Max. Speed: 20.000

Workpieces up to 600 kg

Swivel angle: -120° to +120

Control: Heidenhain TNC 640

Year of manufacture: 2016 & 2018

travels:

x/y/z 1150x700x550 mm

Details:

Max. Speed 18.000

Workpieces up to 1.500 kg

Control: Heidenhain TNC 640

Year of manufacture: 2015

2x Hermle C32 - 5-axis milling machine with swivel table

Travels:

x/y/z 650x650x500 mm

Details:

Max. Speed: 18.000

Workpieces up to 600 kg

Swivel angle: -130° to +130

Control: Heidenhain TNC 640

Robot RS 1

Automation solution for parts and pallet handling

Year of construction: 2021

OTHER TECHNIQUES

OTHER TECHNIQUES

FURTHER

TECHNIQUES

Traverse paths:

grinding length: 1250 mm

grinding width: 600 mm

grinding height : 700 mm

Table load : 1.500 kg

Details:

Guide system: Linear guide

guideway lubrication: fluid grease, automatic

table clamping surface: 1250 x 500 mm

table longitudinal stroke: max. 1550 mm

grinding path adjustment: by means of incremental measuring system

Drive hydraulics: external monoblock

table feed: 2 - 35 m/min

Year of construction: 1998, overhaul 2021

travels:

Measuring range: 700/700/600 mm

details :

Workpieces up to 560 kg

Year of manufacture: 2007

Travel distances:

Measuring range: 300 x 200 x 75 mm

Details:

Chamber measuring system, light sensor, height sensor, coaxial lighting unit

Year of construction: 2022

Travel distances:

Measuring plate 390 x 450 mm

Details:

350 mm Z-axis, 140 mm X-axis, 60 mm Y-axis, measuring range 70 mm

Year of construction: 2023

Travels:

Max. Workpiece dimensions 680 x 500 x 700 mm

Details:

Year of manufacture: 2014