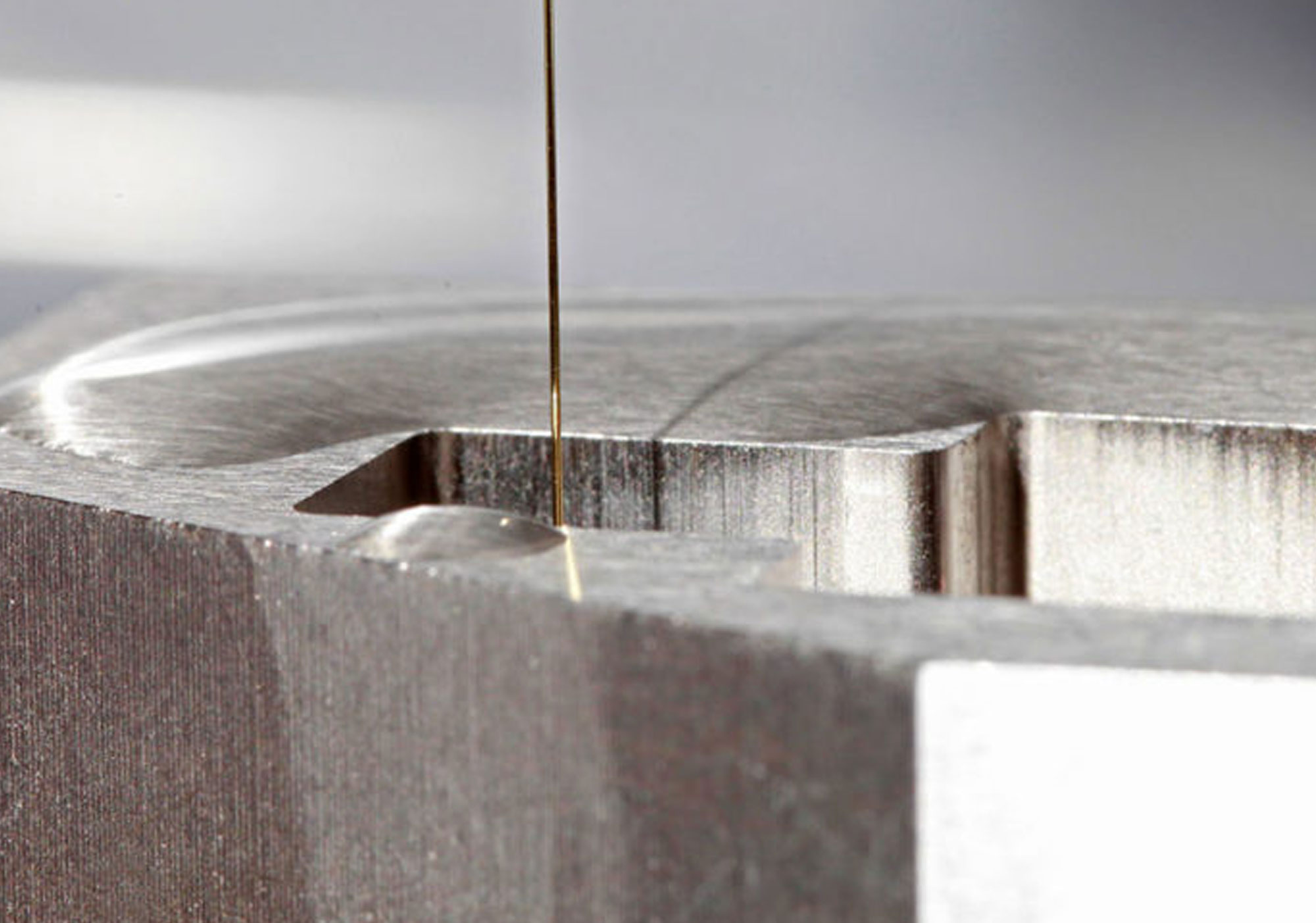

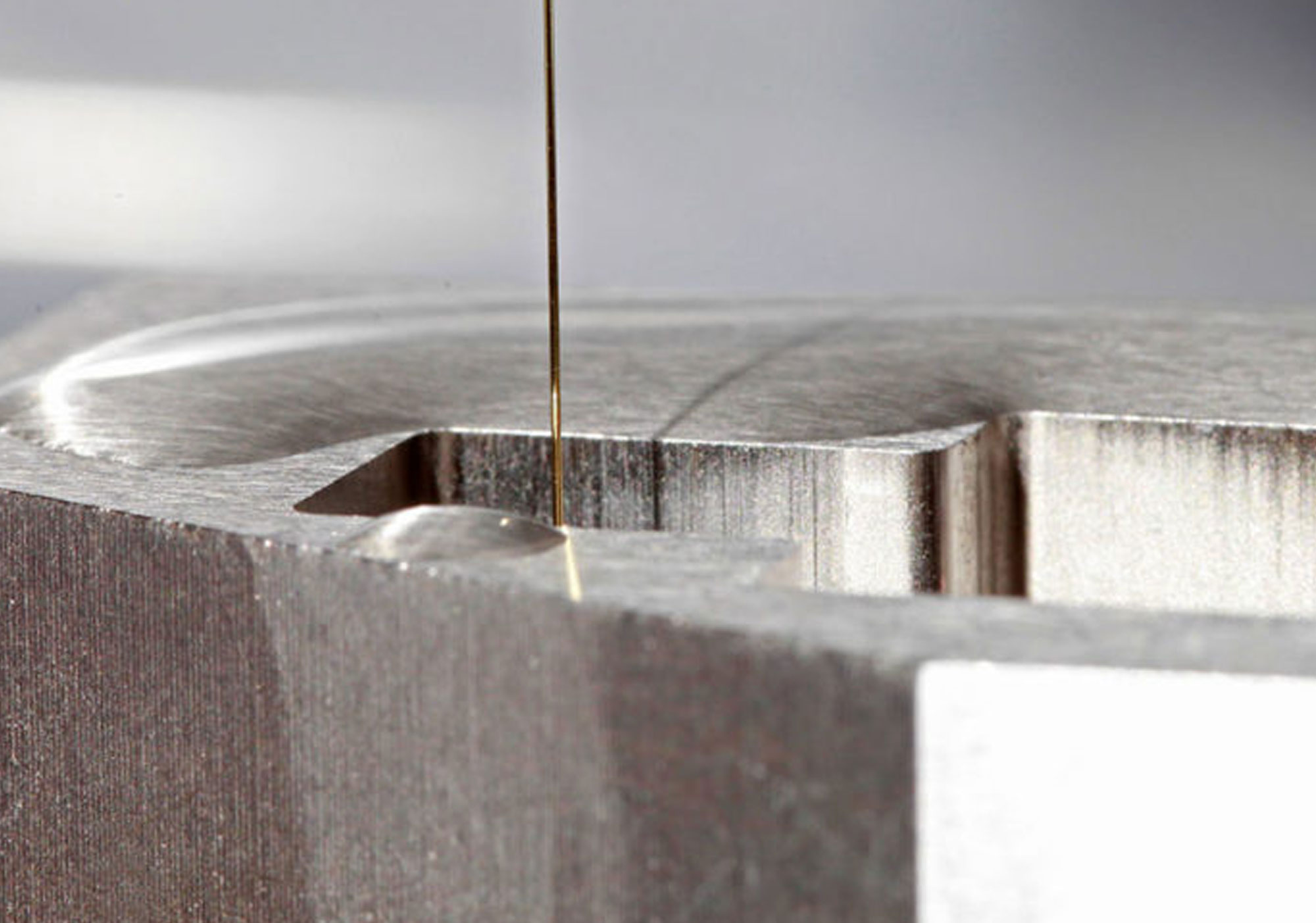

Cutting with the hot wire

Cutting with the hot wire

Presentation of our wire EDM department

Presentation of our wire EDM department

Wire EDM has been a core competence since the very beginning. It all began 25 years ago with the development and production of the retractor system Condor GoldLine for medical technology. Today, we also offer the process and our many years of expertise outside of medical technology. and secondly, we offer it to our customers as a service. We understand the challenges and the needs of our customers because we question and experience them. Only then are we able to act as problem solvers and develop actual solutions.

Advantages of wire erosion

- Low waiting times

- Machining of any material thickness and also small cutting widths are possible

- Wire erosion of almost all contours thanks to starting hole drilling machine as well as professional wire erosion machines

- Highest quality dimensional accuracy and precise wire erosion for every workpiece

Wire EDM has been a core competence since the very beginning. It all began 25 years ago with the development and production of the retractor system Condor GoldLine for medical technology. Today, we also offer the process and our many years of expertise outside of medical technology. and secondly, we offer it to our customers as a service. We understand the challenges and the needs of our customers because we question and experience them. Only then are we able to act as problem solvers and develop actual solutions.

Advantages of wire erosion

- Low waiting times

- Machining of any material thickness and also small cutting widths are possible

- Wire erosion of almost all contours thanks to starting hole drilling machine as well as professional wire erosion machines

- Highest quality dimensional accuracy and precise wire erosion for every workpiece

Modern machinery and the know-how of our employees are the basis for highest quality and precision. Our machine park with seven wire eroding machines from the manufacturer Mitsubishi Electric offers continuous quality and a high degree of flexibility. Our goal is to always work with state-of-the-art technology and to meet the increasing demands of our customers. We offer reliable wire eroding at top level, highest shape accuracy and finest surfaces of conductive materials - regardless of their hardness.

The success of our specialisation - precise processing down to the µm range - proves anew every day that quality is no coincidence. Many years of experience paired with the latest production technology is the basis of our high manufacturing quality "Made in Germany".

Modern machinery and the know-how of our employees are the basis for highest quality and precision. Our machine park with seven wire eroding machines from the manufacturer Mitsubishi Electric offers continuous quality and a high degree of flexibility. Our goal is to always work with state-of-the-art technology and to meet the increasing demands of our customers. We offer reliable wire eroding at top level, highest shape accuracy and finest surfaces of conductive materials - regardless of their hardness.

The success of our specialisation - precise processing down to the µm range - proves anew every day that quality is no coincidence. Many years of experience paired with the latest production technology is the basis of our high manufacturing quality "Made in Germany".