Managing

Partner

Benedict Rotte

The company Condor has been our supplier for a long time. The short ways, professional competence and the high technological standard are decisive for us. The company Ulrich Rotte Anlagenbau und Fördertechnik has been a specialist supplier for automation technology, robotics and special systems since 1994. Innovative solutions belong to our daily business. Together with Condor we could prove our innovative spirit again. On our own initiative, Condor presented us with a vacuum gripper which had previously been a classic component from the metalworking industry in our plant engineering department. Not only were we able to reduce the weight of the vacuum gripper by 72%, but we were also able to completely simplify assembly, so that assembly costs were also reduced by around 40%. The component was not even redesigned in the first model and will certainly offer us further material savings potential in the future.

We will continue to work on further innovative customer solutions, especially with Condor!

Managing

Partner

Benedict Rotte

Managing

Partner

Benedict Rotte

ROTTE PLANT ENGINEERING &

CONVEYING TECHNIQUES GMBH

The company Condor has been our supplier for a long time. The short ways, professional competence and the high technological standard are decisive for us. The company Ulrich Rotte Anlagenbau und Fördertechnik has been a specialist supplier for automation technology, robotics and special systems since 1994. Innovative solutions belong to our daily business. Together with Condor we could prove our innovative spirit again. On our own initiative, Condor presented us with a vacuum gripper which had previously been a classic component from the metalworking industry in our plant engineering department. Not only were we able to reduce the weight of the vacuum gripper by 72%, but we were also able to completely simplify assembly, so that assembly costs were also reduced by around 40%. The component was not even redesigned in the first model and will certainly offer us further material savings potential in the future.

We will continue to work on further innovative customer solutions, especially with Condor!

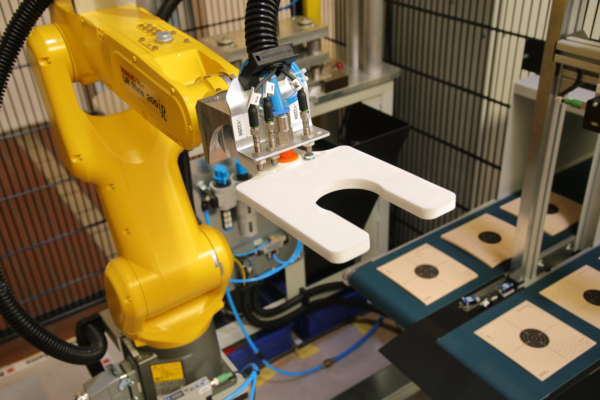

VACUUM GRIPPER & PUNCHING TOOL

Low-weight vacuum gripper thanks to 3D technology from Fa. Condor

6-axis robot with vacuum gripper under the punching tool

Compact robotic cell for automated perforation of moulded parts

Robot cell with deposit table for various vacuum grippers